History.

Its serial number is 508 which places manufacture around 1950/51. Its history isn't known but it has probably been a toolroom machine. It clearly hasn't been abused judging by its table which has a few small cutter scars (see below), but nothing like the holes and gouges you sometimes see.

Size.

One advantage of the M1 is that it can be broken down into half a dozen lumps for transport or moving through narrow doorways and then quickly reassembled in-situ. In fact the main body can be lifted by two biggish blokes, but in any case can easily be moved on a small sack trolley. The base footprint is 17"x28" and is flat enough to be rolled on pieces of pipe. The swarf tray is 28"x38" but could be cut down pretty easily if you're short of space, or re-angled (mitred) at the rear if you need to position it into a corner. A new tee-link spindle belt has been fitted to make future maintenance easier.

Power.

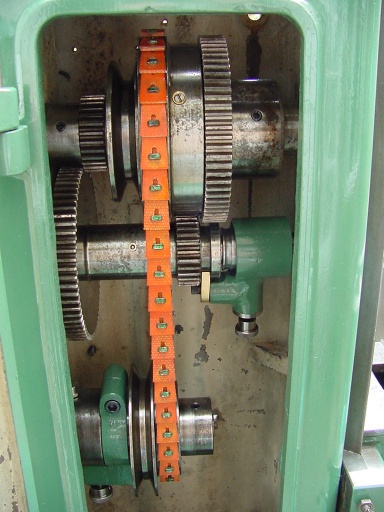

The M1 has a very useful table power-feed driven from the main motor with lever-selectable low, medium and high feed rates available giving 0.0045", 0.009" and 0.018" per rev. An automatic powerfeed 'knock-off' facility is built into the table stops so you can relax and make a cuppa during lengthy operations. No more endlessly winding the handle back and forth on long cuts. Power feed also does wonders for the finish you'll achieve. Dials are imperial and satin chromed for easy reading and nice big handles are fitted for better control. The motor is the original 1hp 3ph unit but it has been rewired to 'delta' pattern and is therefore ready for inverter speed control (0.75kW or above). Just connect the three wires and earth from your inverter and you'll be up and running from a single-phase domestic supply.

Fitting a vertical head.

A unique feature of this individual machine is the specially designed head mounting block included. Cut on the M1 from a solid block of steel, it bolts on top of the body as shown above and provides an ultra-rigid fixing surface for almost any vertical head you care to use. This could include self-powered swivelling quill heads such as the Emco, Dore-Westbury, Astra, Rishton or Tom Senior S-type. Even a Bridgeport head could be fitted here. Normally, fitting a vertical head to a horizontal mill leaves a very reduced machining space under the cutter. However, this block mounts the head much higher, giving the sort of machining room you'd expect from a conventional vertical mill. Crucially, it will also allow you to extend the overarm fully and use horizontal mode without unshipping the vertical head - a major advantage in my opinion. The block has been left undrilled on the front face, ready to be adapted to your particular head.

Main features:

- Small footprint compared with many similar machines. Ideal for workshops that need more capacity but have difficult access

- Horizontal with unusually good vertical potential

- Possibility to change from vertical to horizontal and back again with no loss of head settings

- Horizontal mode allows you to turn traction engine wheels and suchlike that are too big to turn in your lathe. (Fit a faceplate and you have a stub lathe that will swing over 2 feet in diameter!)

- Table has 3-speed power feed driven by main motor, with automatic feed 'knock-off' set by RH table stop

- Very sturdy construction without the floor-buckling weight of some of its contemporaries

- Excellent resale value

- 3 MT horizontal socket

- On maker's cabinet stand

- Can be split into moveable units to fit through domestic doorways

- British designed and made

- No complicated wiring. Just plug three wires into your inverter and you're in business - get any speed without changing a single belt

- Imperial dials with satin chrome finish

- Table size: 25 x 6.25"

- Three tee slots: 1/2" wide slots (to take 3/8" studs)

- Travel: x - 15.5", y - 5.5"", z - 14"

- Overall height: 65"

- Weight: around 800lbs (360kgs)

Wear and tear.

There's some wear in the feed nuts as you'd expect, but all used machines possess a certain amount which just needs to be allowed for when machining. New feed nuts can be made up by RDG (of eBay fame) among others, or rough cut in your own workshop and precision finished with an acme tap from Tracey Tools. (Or fit cheap DRO scales and forget about backlash forever.) The table has some small cutter marks (see right) plus the usual scattering of tiny nicks - not mint, but clean and true. The machine came with a rather odd non-standard coolant pump which I've removed as it leaked and didn't seem up to the job. Fitting a cheap external pump and tank would be the best solution if you need to use coolant.

Tooling.

The machine comes with its original 1" diameter horizontal arbor and support bracket, a 3MT drawbar, a 2MT to 3MT feed-through morse taper adapter (without tang) which allows you to use any existing 2MT tooling you may have and pull it up tight through the adapter with a 2MT drawbar. There's also a small tin of the current paint colour included with the machine in case you need to touch up any chips or make some small attachments.

Transport.

Buyers will need to arrange their own collection and transport. A pallet truck would be ideal for movement if you have one, as the machine is already on a pallet. If you have a lowish trailer I could probably lift it on for you with an engine crane. Otherwise you could hire a small van and load the M1 as separate main parts for later reassembly.

Any questions, just email:

web dot master at riscy dot uk

For more information on Tom Senior mills, visit my links page.

© neil f, 2003

Back to home page