Horizontal mill, vertical mill and drill in one compact unit

Main features:

- Very small footprint. Ideal for small workshops

- Vertical and horizontal capability in one machine

- Self-powered head, so no compromise on speed ranges

- Change from vertical to horizontal in seconds and back again with no loss of head settings

- Horizontal mode can be a way to turn wheels and suchlike that are too big to turn in your lathe. (Think of it as a stub lathe that will swing up to 2' in diameter!)

- Head can be fitted or removed via just three bolts

- Head swivels 360 degrees

- Table has rapid-traverse lever option as well as feed screw - could be useful for light slotting, graduating (see below) or perhaps surface grinding

- Sturdy construction minimises chatter

- Head can extend out on overarm to reach awkward surfaces

- 2 MT sockets

- On maker's steel cabinet stand with large built-in storage cupboard

- Splits into moveable units. Packs into medium hatch/estate. Fits through domestic doorways.

- British designed, Italian made

- Horizontal and vertical modes have separate motor switches

- No complicated wiring. Just plug three wires into your inverter and you're in business - get any speed without changing a single belt

- Vee ways fitted with neat custom-made swarf covers

- New drive belts fitted

- Vertical socket has 'tang catcher' so drill chucks can't spin and spoil socket

This is the machine shot at average eye height to give a more accurate feel for its moderate size. You can see the switch to horizontal mode is made simply by moving out the overarm.

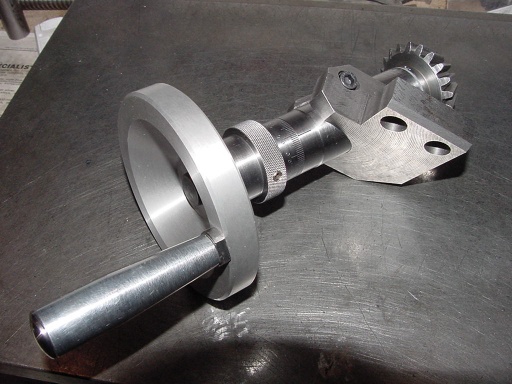

This is the newly made vertical feed unit before painting.

Vertical feed components. A ball thrust bearing was added before assembly.

| X travel | --- | 12.5" |

| Y travel | --- | 4.75" |

| Vertical travel | --- | 12" |

| Table size | --- | 16.5" x 4.75" |

| Sockets | --- | 2 MT |

| Base footprint | --- | 18" x 23" |

| Overall height | 75" | |

| Tee slots | --- | 2 (0.375" slots) |

| Table dials | --- | Imperial |

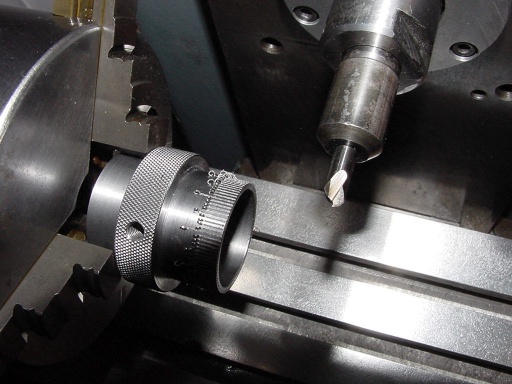

This shows an interesting use of the horizontal mode - graduating the table-feed dial using the Astra's lever crossfeed and table stops.

© neil f

web dot master at riscy dot uk

More information on Astra mills can be found at:

www.lathes.co.uk/astra/index.html

Back to home page